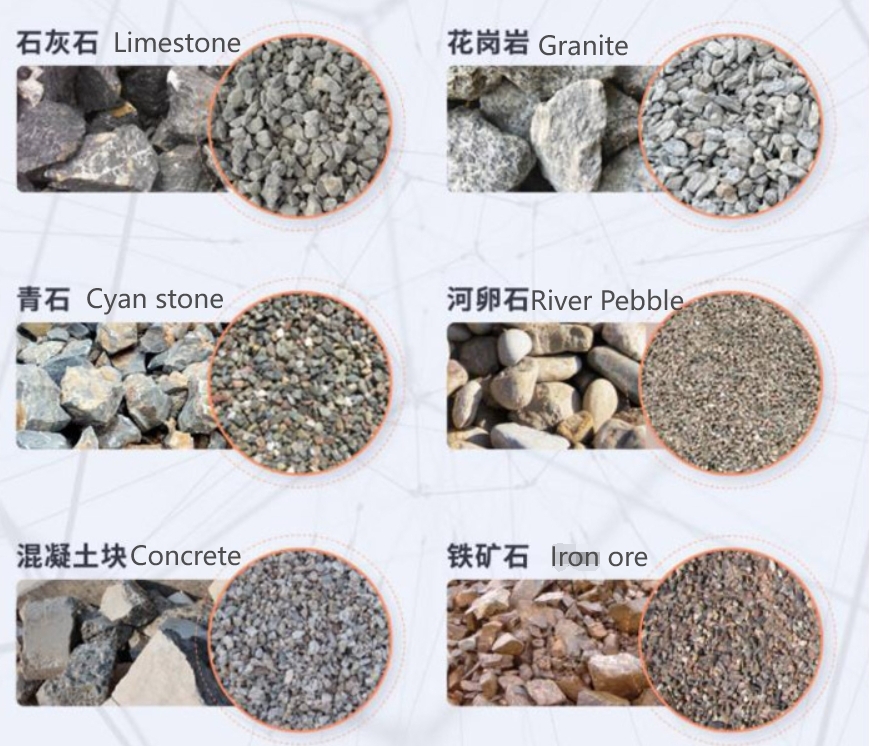

Impact crusher is mainly used for material processing in metallurgy, chemical industry, building materials, hydropower and other industries that often need to be relocated, especially for the operation of mobile stone materials such as highways, railways, hydropower projects, etc., and can be configured in various forms according to the type, scale and requirements of finished materials. Impact crusher can perform coarse crushing and secondary crushing of limestone, bluestone and other materials with medium hardness below 80 MPa, and is mainly used in sand and gravel production in highway, railway, water conservancy, electricity, construction and other industries.

Impact crusher is mainly used for material processing in metallurgy, chemical industry, building materials, hydropower and other industries that often need to be relocated, especially for the operation of mobile stone materials such as highways, railways, hydropower projects, etc., and can be configured in various forms according to the type, scale and requirements of finished materials. Impact crusher can perform coarse crushing and secondary crushing of limestone, bluestone and other materials with medium hardness below 80 MPa, and is mainly used in sand and gravel production in highway, railway, water conservancy, electricity, construction and other industries.

The rotor crushing chamber independently developed by STRONG impact crushing station is larger than that on the market, and the feed diameter is also larger, which can provide stronger rotational inertia and plate hammer impact force, so as to achieve a larger crushing ratio with fewer crushing stages and reduce investment costs. It is randomly equipped with diesel engine set and inverter, which can save on-site installation and commissioning time, make movement and transfer more convenient, and greatly improve construction efficiency.

Features

The processing capacity can reach up to 260 tons/hour;

Light structure design, easy to transport, optional return screening system for closed-circuit production;

SF260C is a electric engine drive 3 layers screen type, which is popular in domestic market,it equipped with a walking drive diesel engine, connected to the power grid in the working mode, and can be equipped with a diesel generator set; it has own diesel generator set (Deutz 500 type), which can be switched to an external power grid. It ba can directly produce three kinds of finished materials.

Technical Parameter

| Model: | SF260C |

| Weight: | 55 |

| Handling capacity: | 120-260 |

| Total equipment power (kW): | 315 |

| Diesel engine power (kW): | 440 |

| Crusher power (kW): | 250 |

| Dimensions (L*W*H): | 19000*7900*4750 |

| Transportation dimensions (L*W*H): | 16000*3200*3800 |

| The max feeding size:(mm) | 600 |

| The motor power of vibration feeder(kW): | 3.7kW*2 |

| The motor power of vibrating screen(kW): | 4.5kW*2 |

| Vibrating screen size (L*W): | 4000*1500mm |

| Hopper capacity (m³) | 6m³ |

| Travel diesel engine power (kW): | 90 |

| Crusher rotor size (L*D) | 1270* Φ1240mm |